A flywheel is usually coupled to the crank shaft to limit the fluctuation of turning moment and hence the fluctuation of speed. 1First the amount of energy required for the desired degree of smoothening must be found and the mass moment of inertia needed to absorb that energy determined.

Design Of Flywheel And Simple Solved Problems On Flywheels Youtube

As per as design of flywheel is concerned it is required to decide the mean diameter of the flywheel rim which rely upon mainly two factors such as availability of space and the limiting value of peripheral velocity of the fly wheel.

. Therefore once the component suffers from a bad driving style for a while it will result in an unexpected malfunction in the. Hi i tell all about it. A new approach to the problem of flywheel design has been developed thus eliminating some of the problems of conventional design.

Cast steel 7800 kgm 3. The material of flywheel on most applications will be either cast iron or cast steel. R1 Flywheel inner radius.

We attach generator to charge batteriesour gear setup give as 3500 rpm and that shaft connected to flywheel kmax speed 3500 and min 1000we use hub motor for front wheel and we use both manual and electric we charge batteries for hub motorgive me. 2142006 ACRME2092006 2142006 ACRME2092006 Design of a Flywheel. Procedure Design of a Flywheel.

Choose a suitable value for coefficient of fluctuation of. Figure 1 - Flywheel Design. Dual mass flywheels appear to be a better option than single-piece flywheels especially due to the absence of noise and vibrations.

Up to 5 cash back CHAPTER 19 Flywheel Chapter Objectives Determine the maximum fluctuation of energy from torque versus angular displacement diagram for a given problem. 18 Design of flywheel problems 19 Design of crank shaft problems 20 Design of valves problems Assignment 2. The efficiency of the mechanical drive is 95.

R2 Flywheel outer radius. 45 Flywheel Design 451 Mass Moment of Inertia of Flywheel for an IC Engine 452 Mass Moment of Inertia of Flywheel for a Punching Press 453 Design of Flywheel 46 Summary 47 Key Words 48 Answers to SAQs 41 INTRODUCTION In practice there are two following types of cases where reciprocating engine mechanism is used. Design Of Flywheel Problems.

A numerical scheme for optimum design of flywheels is considered in this paper. - Selection from Machine Design Book. Design of friction type clutches problems 22 Design of clutches centrifugal type problems 23 Problems on design of clutches 24 Design of straight and helical spur gears problems.

First a continuous function is devised for thickness variation of the flywheel. The ultimate shear strength of the steel plate is 450 MPa. The speed of the flywheel is 10 times the speed of the crankshaft.

Procedure Selection of the engine Calculation of torque due to inertia forces The total Inertia force Q M x Data. The empathy stage is where the problem solver tries to understand the audience. Although the exact relationship depends on the flywheel design in general the maximum rotational velocity and specific energy of a flywheel are proportional to the allowable working strength divided by the density of the rotor material.

Design a rimmed flywheel if mean radius of rim is 05 m and ρ of CI used for flywheel is 7150 kgm 3. However the component requires a nice driving style to maintain its efficiency and reach its lifespan. Design of Flywheel and Simple Solved Problems on Flywheels.

Design of flywheel problems Nail artwork conjures up All peopleIf you are a colorful Woman Then you can certainly take up brighter color tones to your nails if you want delicate issues so certainly your mood will pick up on nail paints which are a little bit uninteresting and fewer flashy. The Density of the materials d is as follows. The constraints such as stress constraints volume constraints and linear geometric constraints are used while solving the optimization problem.

2Then flywheel geometry must be defined that caters the required moment of inertia in a reasonably sized. Calculation of the flywheel mass. A large flywheel is needed to smooth the output from a single cylinder engine as excessive vibration can cause problems with parts resonating and fatiguing and nuts and bolts working loose.

Assume that 90 of moment of inertia of flywheel is. Arial Garamond Times New Roman Wingdings Edge Flywheel Problem Finding acceleration and velocity Finding acceleration and velocity Kinetic Energy Material consideration Stress-Strain relations Stress-Strain relations Stress-Strain relations Equation of Motion for ur Equation of Motion for ur Stress field Stress field Product bound. Numerical Problems on Flywheel Design Turning Moment Diagrams Maximum Fluctuation of Energy Dimensions of a Flywheel Rim Dynamics of Mach.

Cast iron 7250 kgm 3. Design of high energy density flywheels to operate at the maximum rotational speed. Flywheel Design Critical Dimensions.

The stress analysis problem is presented as a two-point boundary-value differential equation. DESIGN OF FLYWHEEL Design Equation- IS 𝑬 𝒌 𝑪 𝒇 𝝎 𝒂𝒗𝒈 𝟐 where Cfis the co-efficient of speed fluctuation and Ekis the kinetic energy and 𝝎avg is the average rotational motion. One of the persistent problems of flywheel design is the attachment of the rim typically made of filament- wound carbon fiber composite materials with a hub that mates to bearings and a motorgenerator.

There are two stages to the design of a flywheel. I ll attach gear setup in rear sprocketand fly wheel connected to gear arrangement. The punching operation takes place in 16 th of the cycle.

4 21 III25 Design of transmission components. The flywheel is maximized by maximizing the polar moment of inertia equation of the flywheel. After all two people may have the same problem but with different contexts.

The term flywheel design in this thesis refers to the the determination of the flywheel iner tia mass moment of inertia only. Expressions are then provided for calculation of volume and mass moment of inertia. The process involved in design thinking applies five different principles that often makes it more effective than the traditional method.

Traditional designs are open. Single cylinder low speed diesels need particularly heavy flywheels because they have large heavy pistons and connecting rods which run at low speeds.

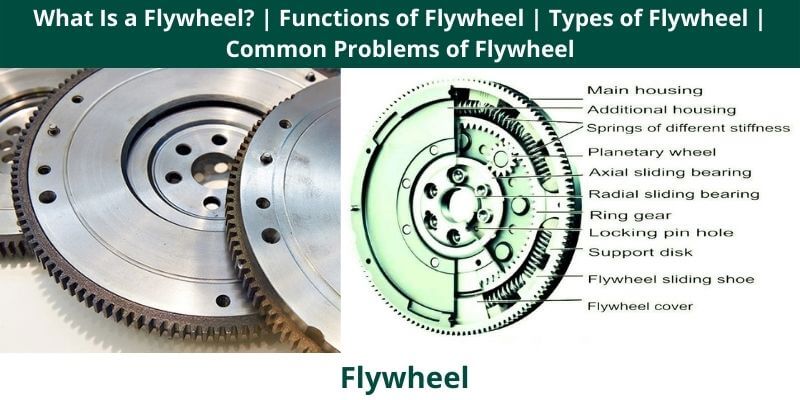

What Is A Flywheel Functions Of Flywheel Types Of Flywheel Common Problems Of Flywheel

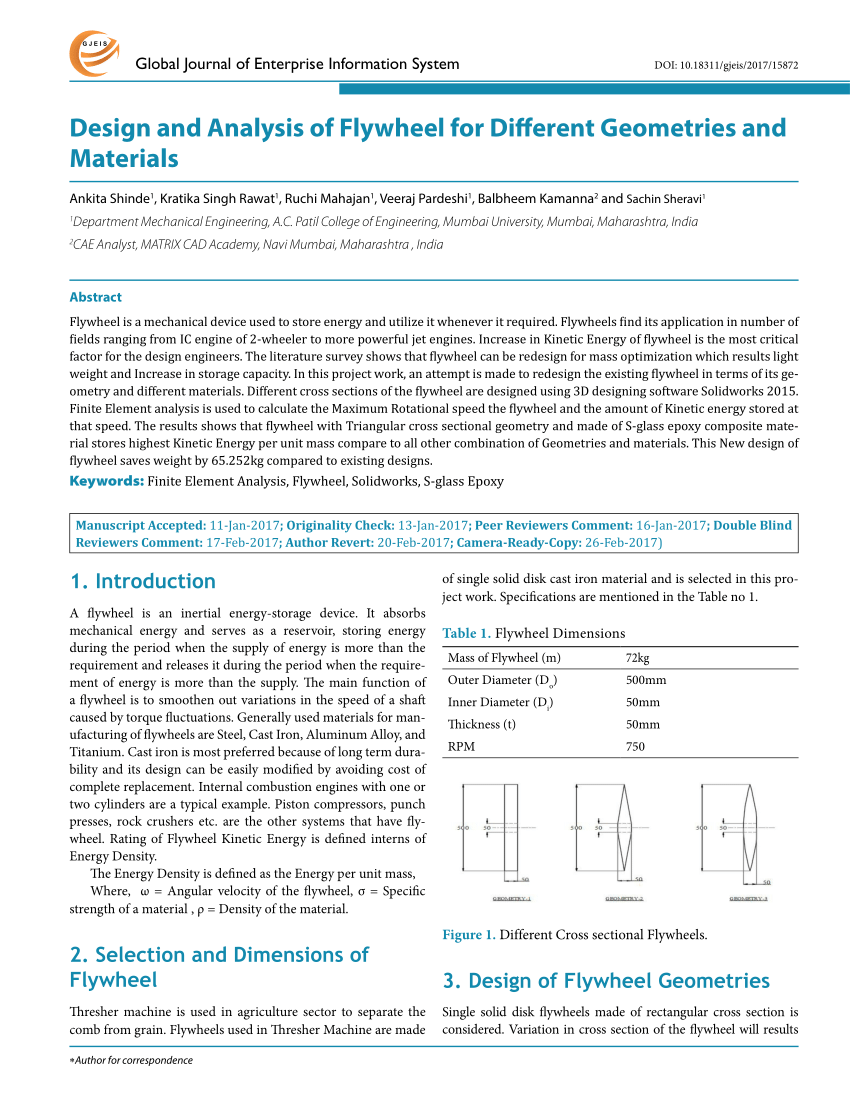

Pdf Design And Analysis Of Flywheel For Different Geometries And Materials

Design And Analysis Of Flywheel For Weight Optimization By International Journal For Scientific Research And Development Ijsrd Issuu

Solved Design Specifications Require A Shaft With A Flywheel Chegg Com

Lecture 17 Type Ii Numerical Problem On Flywheel Design Dynamics Of Machines Dom Youtube

0 comments

Post a Comment